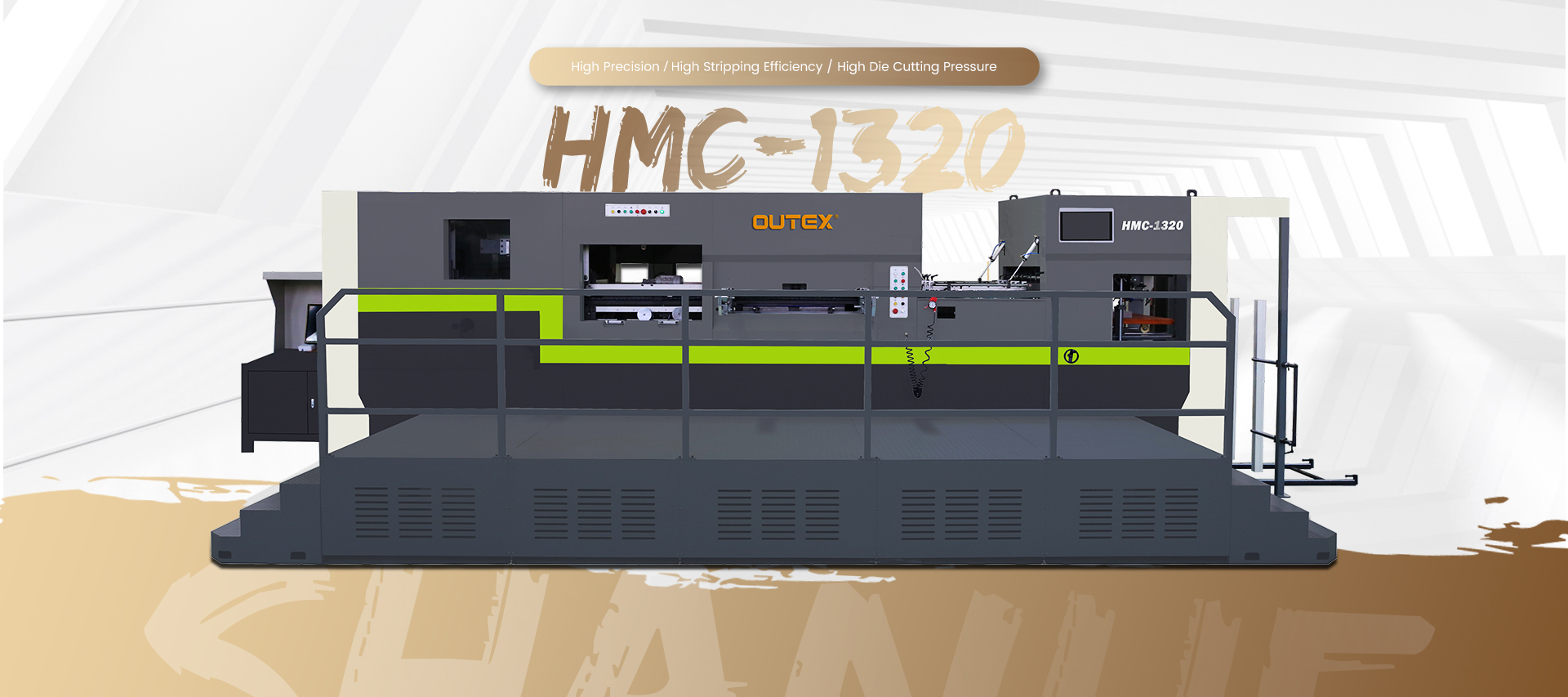

I-HMC-1320 Automatic Die Cutting Machine

INKCAZO

| I-HMC-1320 | |

| Ubukhulu. usayizi wephepha | 1320 x 960mm |

| Okuncane. usayizi wephepha | 500 x 450mm |

| Ubukhulu. die cut size | 1300 x 950mm |

| Ubukhulu. isivinini sokugijima | 6000 S/H (iyahlukahluka kuye ngosayizi wesakhiwo) |

| Ukukhumula isivinini somsebenzi | 5500 S/H (ama-aries ngokosayizi wesakhiwo) |

| Die cut ngokunemba | ±0.20mm |

| Ubude benqwaba yokufaka iphepha (kuhlanganise nebhodi laphansi) | 1600 mm |

| Ukuphakama kwenqwaba yephepha (kuhlanganise nebhodi laphansi) | 1150 mm |

| Ukujiya kwephepha | amakhadibhodi: 0.1-1.5mm ibhodi likathayela: ≤10mm |

| Ibanga lokucindezela | 2mm |

| Ukuphakama komugqa we-blade | 23.8mm |

| Isilinganiso | 380±5%VAC |

| Ubukhulu. ingcindezi | 350T |

| Inani lomoya elicindezelwe | ≧0.25㎡/min ≧0.6mpa |

| Amandla emoto amakhulu | 15KW |

| Amandla aphelele | 25KW |

| Isisindo | 19T |

| Usayizi womshini | Akubandakanyi i-pedal yokusebenza kanye nengxenye yokupakisha ngaphambilini: 7920 x 2530 x 2500mm Faka i-pedal yokusebenza kanye nengxenye yokupakisha ngaphambilini: 8900 x 4430 x 2500mm |

IMINININGWANE

Lo mshini womuntu uzothuthukisa ukusebenza kahle komshini ngohlelo lokulawula ukunyakaza oluhlanganiswe ngokuphelele ne-servo motor, oluqinisekisa ukuthi konke ukusebenza kungashelela futhi kusebenze kahle kakhulu. Iphinde isebenzise umklamo oyingqayizivele wesakhiwo sokumunca iphepha ukuze wenze umshini uvumelane nebhodi lephepha likathayela eligobile uzinze kakhudlwana. Ngedivayisi yokudla engayeki kanye nesengezo sephepha kukhulisa kakhulu ukusebenza kahle. Ngesicoci semfucuza esizenzakalelayo, singasusa kalula imiphetho emine kanye nembobo ngemva kokusika imfucuza. Umshini wonke usebenzisa izinto ezingenisiwe eziqinisekisa ukuthi uzinzile futhi uhlala isikhathi eside ukusetshenziswa kwawo.