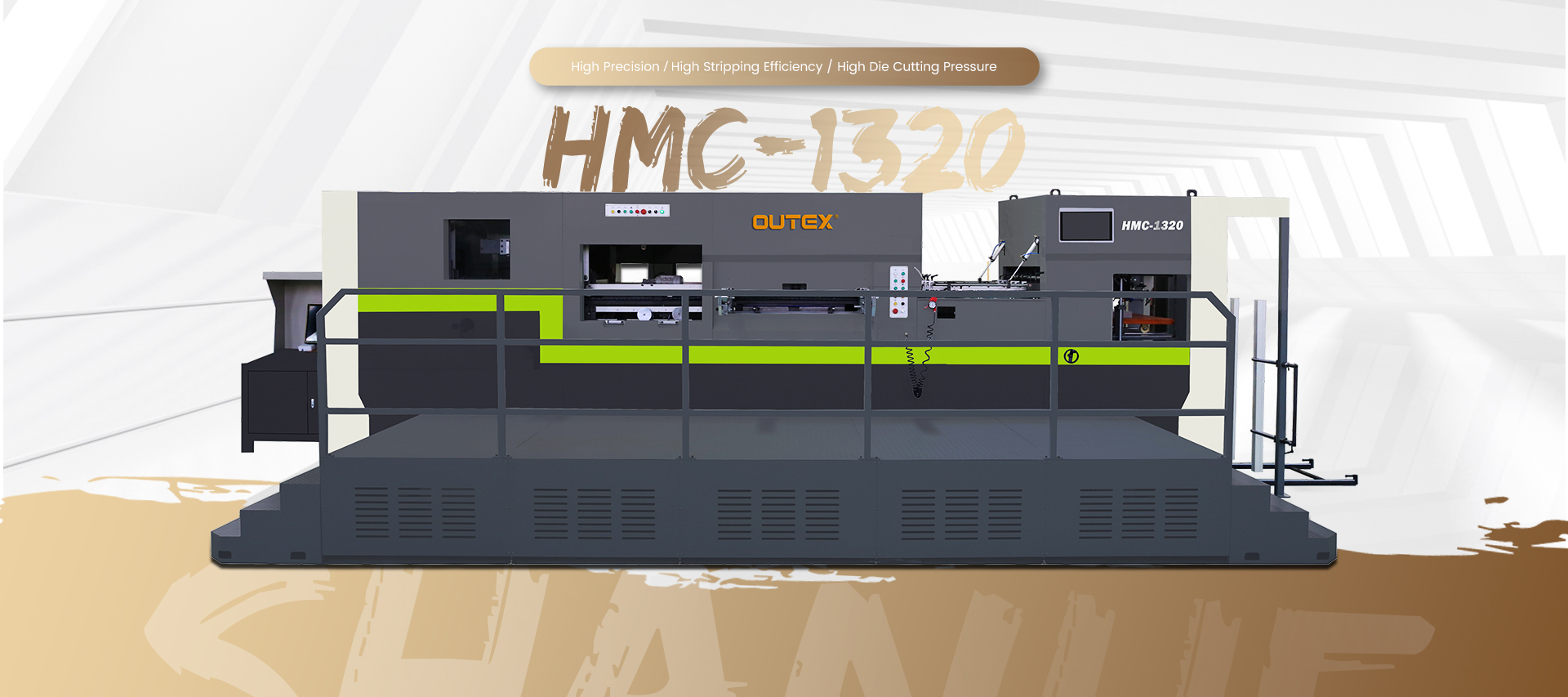

HMC-1320 Automatic Die Cutting Machine

INGCACISO

| HMC-1320 | |

| Max. ubungakanani bephepha | 1320 x 960mm |

| Min. ubungakanani bephepha | 500 x 450mm |

| Max. fa cut size | 1300 x 950mm |

| Max. isantya sokubaleka | 6000 S/H (iyahluka ngokobungakanani boyilo) |

| Ukukhulula isantya somsebenzi | 5500 S/H (iiary ngokobungakanani boyilo) |

| Die cut ngokuchanekileyo | ±0.20mm |

| Ubude bemfumba yegalelo lephepha (kubandakanywa nebhodi yomgangatho) | 1600mm |

| Ubude bemfumba yemveliso yephepha (kubandakanywa nebhodi yomgangatho) | 1150mm |

| Ubukhulu bephepha | ikhadibhodi: 0.1-1.5mm ibhodi emacangci: ≤10mm |

| Uluhlu loxinzelelo | 2mm |

| Ubude bomgca weBlade | 23.8mm |

| Ukukala | 380±5%VAC |

| Max. uxinzelelo | 350T |

| Umthamo womoya oxinanisiweyo | ≧0.25㎡/min ≧0.6mpa |

| Amandla enjini aphambili | 15KW |

| Amandla onke | 25KW |

| Ubunzima | 19T |

| Ubungakanani bomatshini | Ayibandakanyi i-pedal yokusebenza kunye nenxalenye yokupakisha kwangaphambili: 7920 x 2530 x 2500mm Bandakanya i-pedal yokusebenza kunye nenxalenye yokupakisha kwangaphambili: 8900 x 4430 x 2500mm |

IINKCUKACHA

Lo matshini wobuntu uya kuphucula ukusebenza kakuhle komatshini ngenkqubo yokulawula intshukumo edityanisiweyo ngokugqibeleleyo kunye ne-servo motor, eqinisekisa ukuba konke okusebenzayo kunokugudisa kunye nokusebenza okuphezulu. Ikwasebenzisa uyilo olulodwa lolwakhiwo lwephepha lokufunxa ukwenza umatshini ulungelelanise nebhodi yephepha egobileyo yomelele ngakumbi. Ngesixhobo sokutyisa esingayekiyo kunye nesongezo sephepha kwandisa kakhulu ukusebenza kakuhle. Ngesicoci senkunkuma esizenzekelayo, sinokususa ngokulula imiphetho emine kunye nomngxuma emva kokusikwa kokufa. Umatshini wonke usebenzisa amacandelo angaphandle aqinisekisa ukuba uzinzile kwaye uhlala ixesha elide ukusetyenziswa kwawo.