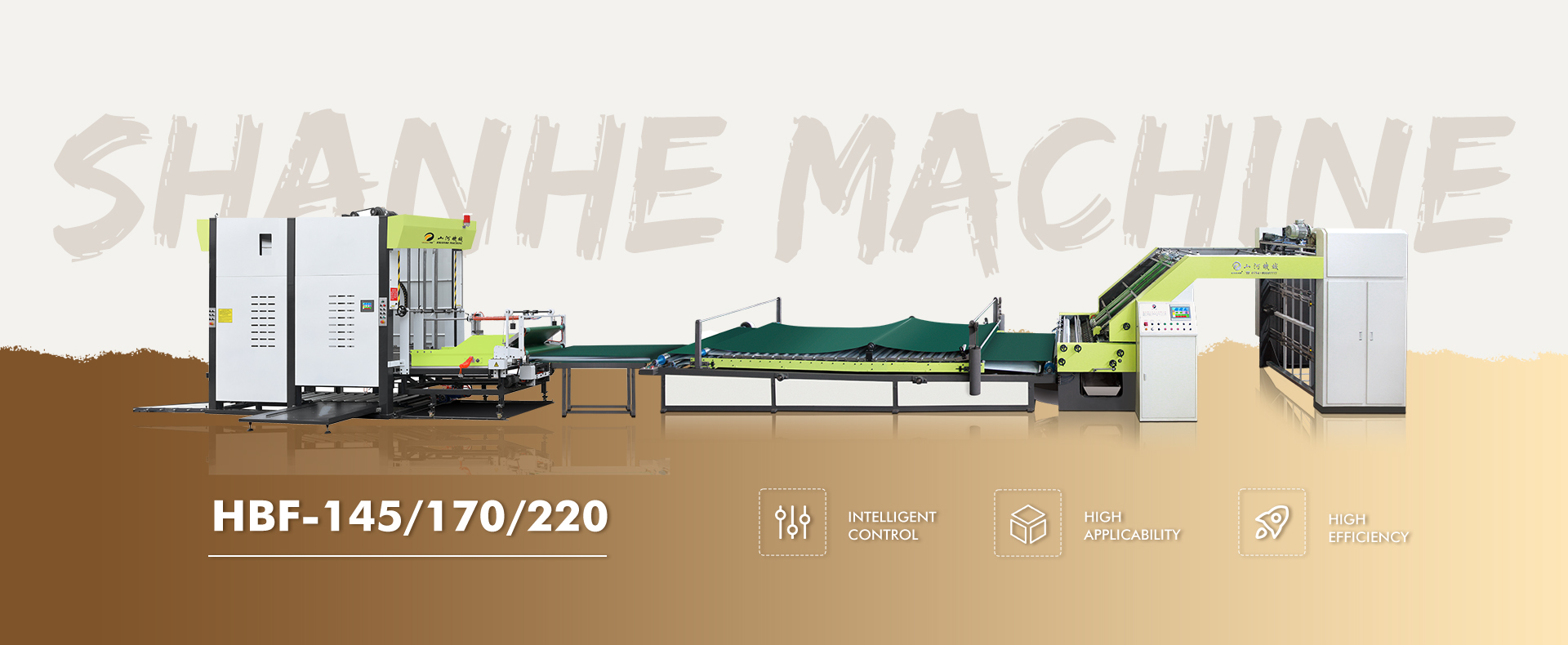

Automatic high speed flute laminator

Re motlotlo ka phethahatso e phahameng ea bareki le kamohelo e pharaletseng ka lebaka la ho phehella ha rona boleng ba boleng bo holimo ka bobeli ba lihlahisoa le tšebeletso bakeng sa Automatic high speed flute laminator, Ho ba teng kamehla ha thepa ea boleng bo phahameng hammoho le e ikhethang ea pele le ka morao. -Thekiso ea tšehetso e netefatsa tlholisano e matla 'marakeng o ntseng o eketseha oa lefatše.

Re motlotlo ka phethahatso e phahameng ea bareki le kamohelo e pharaletseng ka lebaka la ho phehella ha rona ho phehella boleng ba boleng bo holimo ba lihlahisoa le litšebeletso tsaChina jarolla ka ho iketsa lebelo lekolilo laminator, re na le tšepo e tiileng ea ho theha kamano e ntle ea nako e telele ea khoebo le k'hamphani ea hau e hlomphuoang e nahanne ka monyetla ona, o ipapisitse le ho lekana, ho thusa le ho hapa khoebo e atlehileng ho tloha joale ho fihlela nakong e tlang.

BONTŠA SEHLAHISO

TS'ELISO

| HBF-145 | |

| Max. boholo ba leqephe(mm) | 1450 (W) x 1300 (L) / 1450 (W) x 1450 (L) |

| Min. boholo ba leqephe(mm) | 360 x 380 |

| Botenya ba leqephe le holimo(g/㎡) | 128 - 450 |

| Botenya ba leqephe le tlase(mm) | 0.5 - 10 (ha karete ea laminate e ea ho karete, re hloka hore lakane e ka tlase e be ka holimo ho 250gsm) |

| Letlapa le ka tlase le loketseng | Boto e entsoeng ka makotikoti (A/B/C/D/E/F/N-flute, 3-ply,4-ply,5-ply le 7-ply); boto e bohlooho; khateboto; KT board, kapa pampiri ho lamination ea pampiri |

| Max. lebelo la ho sebetsa(m/min) | 160m/min (ha lekolilo le bolelele ba 500mm, mochini o ka fihla ho max. lebelo 16000pcs/hr) |

| Ho nepahala ha lamination(mm) | ±0.5 - ±1.0 |

| Matla(kw) | 16.6 (eseng ho kenyelletsa compressor ea moea) |

| Matla a stacker(kw) | 7.5 (eseng ho kenyelletsa compressor ea moea) |

| Boima(kg) | 12300 |

| Boholo ba mochini(mm) | 21500(L) x 3000(W) x 3000(H) |

| HBF-170 | |

| Max. boholo ba leqephe(mm) | 1700 (W) x 1650 (L) / 1700 (W) x 1450 (L) |

| Min. boholo ba leqephe(mm) | 360 x 380 |

| Botenya ba leqephe le holimo(g/㎡) | 128 - 450 |

| Botenya ba leqephe le tlase(mm) | 0.5-10mm (bakeng sa khateboto ho lamination ea karete: 250+gsm) |

| Letlapa le ka tlase le loketseng | Boto e entsoeng ka makotikoti (A/B/C/D/E/F/N-flute, 3-ply,4-ply,5-ply le 7-ply); boto e bohlooho; khateboto; KT board, kapa pampiri ho lamination ea pampiri |

| Max. lebelo la ho sebetsa(m/min) | 160 m/min (ha o sebelisa pampiri ea boholo ba 500mm, mochini o ka fihla ho max. lebelo la 16000pcs/hr) |

| Ho nepahala ha lamination(mm) | ± 0.5mm ho ± 1.0mm |

| Matla(kw) | 23.57 |

| Matla a stacker(kw) | 9 |

| Boima(kg) | 14300 |

| Boholo ba mochini(mm) | 23600 (L) x 3320 (W) x 3000(H) |

| HBF-220 | |

| Max. boholo ba leqephe(mm) | 2200 (W) x 1650 (L) |

| Min. boholo ba leqephe(mm) | 600 x 600 / 800 x 600 |

| Botenya ba leqephe le holimo(g/㎡) | 200-450 |

| Letlapa le ka tlase le loketseng | Boto e entsoeng ka makotikoti (A/B/C/D/E/F/N-flute, 3-ply,4-ply,5-ply le 7-ply); boto e bohlooho; khateboto; KT board, kapa pampiri ho lamination ea pampiri |

| Max. lebelo la ho sebetsa(m/min) | 130 m/min |

| Ho nepahala ha lamination(mm) | <± 1.5mm |

| Matla(kw) | 27 |

| Matla a stacker(kw) | 10.8 |

| Boima(kg) | 16800 |

| Boholo ba mochini(mm) | 24800 (L) x 3320 (W) x 3000 (H) |

MOLEMO

Sistimi ea taolo ea motsamao bakeng sa ho hokahanya le taolo e kholo.

Sebaka sa maqephe a fokolang se ka ba 120mm.

Li-motors tsa servo bakeng sa ho tsamaisana le boemo ba laminating ea maqephe a ka pele le a ka morao.

Sistimi ea ho latela maqephe a ikemetseng, maqephe a ka holimo a latela maqephe a ka tlase.

Thepa skrine bakeng sa ho laola le ho beha leihlo.

Sesebelisoa sa mofuta oa Gantry o kenyang esale pele bakeng sa ho beha leqephe le ka holimo habonolo.

Vertical Paper Stacker e ka fumana ho amohela pampiri ka bo eona.

LIKAROLOANA

A. TAOLI YA HLALE

● American Parker Motion Controller e tlatsana le mamello ho laola ho tsamaisana

● Japanese YASKAWA Servo Motors e lumella mochine hore o sebetse ka mokhoa o tsitsitseng le o potlakileng

C. KAROLO EA LAOLANG

● Touch Screen Monitor, HMI, e nang le mofuta oa CN/EN

● Beha boholo ba maqephe, fetola sebaka sa maqephe le ho lekola boemo ba ts'ebetso

E. TŠEBELETSO KAROLO

● Mabanta a nako a tsoang kantle ho naha a rarolla bothata ba lamination e sa nepahalang ka lebaka la ketane e tsofetseng

Boto ea Corrugted B/E/F/G/C9-flute 2-ply to 5-ply

Boto ea Duplex

Grey Board

H. KAROLO PELE

● Ho bonolo ho beha qubu ea lakane e ka holimo

● Japanese YASKAWA Servo Motor

MOHLALA HBZ LITLHAKISO

MOHLALA LF LITLHAKISO

LF-145/165 Vertical Paper Stacker ke ea ho hokahana le laminator ea lekolilo le lebelo le phahameng ho hlokomela ts'ebetso ea othomathike ea ho bokella pampiri. E bokella sehlahisoa se felileng sa lamination hore e be qubu ho latela bongata ba ho beha. Mochini o kopanya mesebetsi ea ho phetla pampiri ka linako tse ling, ho bokella pampiri ka lehlakoreng le ka pele ho ea holimo kapa lehlakoreng le ka morao holimo le ho bokellana ka makhethe; qetellong e ka sutumelletsa ka ntle qubu ea pampiri. Ho fihlela joale, e se e thusitse lik'hamphani tse ngata tsa khatiso le tsa ho paka ho sebetsana le bothata ba khaello ea basebetsi, ho ntlafatsa boemo ba ts'ebetso, ho boloka mosebetsi o boima le ho eketsa haholo kakaretso ea kakaretso.

A. MOTS'ELISI

● Sebelisa mabanta a sephara a rabara ho e hokahanya le laminator bakeng sa ho sebetsa ka mokhoa o lumellanang.

● Beha palo e itseng ea pampiri ea stacking, ka ho fihla nomorong eo, pampiri e tla romelloa ho yuniti e feto-fetohang (ho tsamaisoa ha pele).

● E phaphatha pampiri ho tloha ka pele le mahlakoreng a mabeli ho etsa hore pampiri e bokelloe ka makhethe.

● Maemo a nepahetseng a ipapisitse le theknoloji ea maqhubu a feto-fetohang.

● Ho sututsa pampiri ka enjene.

● Ho sututsa pampiri ka thata.

C. PHAPALATSO

● Ha pampiri e qala ho romelloa yuniti e phetholang, mochini o phahamisang o tla phahamisetsa pampiri bophahamong ba ho seta.

● Nakong ea ts'ebetso ea bobeli ea ho fana, pampiri e tla romelloa ho stacker e kholo.

● Maemo a nepahetseng a ipapisitse le theknoloji ea maqhubu a feto-fetohang.

● Ho phethola pampiri e khannoang ka enjene. Pampiri e ka phutheloa ka lehlakore le le leng le ka pele holimo le qubu e le 'ngoe ka morao holimo ka ho fapanyetsana, kapa kaofela li na le mahlakore a tsona a ka pele holimo le mahlakore a tsona a ka morao holimo.

● Sebelisa enjene e feto-fetohang ho sututsa pampiri.

● Sekeno sa terei.

● Taolo ea skrine ea ho ama.

● Ho ema ka morao, le ho phaphatha pampiri ho tloha mahlakoreng a 3: lehlakoreng le ka pele, lehlakoreng le letšehali le lehlakoreng le letona.

● Sesebediswa se behang esale pele bakeng sa ho fihla ha nako e sa kgaotseng.

● Pampiri stacking bophahamo ba fetoha pakeng tsa 1400mm ho 1750mm. Bophahamo bo ka eketsoa ho latela litlhoko tsa bareki.

G. HO FUMANA KAROLO

● Ha stacker ea pampiri e tletse, enjene e tla khanna pampiri ka bo eona.

● Ka nako e ts'oanang, tray e se nang letho e tla phahamisetsoa sebakeng sa pele.

● Phula ea pampiri e tla huloa ke jeke ea pallet ho tloha letsoapong.

| Mofuta oa Mosebetsi | Sephetho sa Hora |

| E-flute e le 'ngoe | 9000-14800 p/h |

| B-flute e le 'ngoe | 8500-11000 p/h |

| E-flute e habeli | 9000-10000 p/h |

| 5 ply BE-folutu | 7000-8000 p/h |

| 5 ply BC-folutu | 6000-6500 p/h |

| PS: lebelo la stacker le itšetlehile ka botenya ba sebele ba boto | |

Re motlotlo ka phethahatso e phahameng ea bareki le kamohelo e pharaletseng ka lebaka la ho phehella ha rona boleng ba boleng bo holimo ka bobeli ba lihlahisoa le tšebeletso bakeng sa laminator ea lebelo le phahameng la lekolilo, ho ba teng ho tsoelang pele ha thepa ea boleng bo phahameng hammoho le tse ikhethang tsa pele le ka morao. -Thekiso ea tšehetso e netefatsa tlholisano e matla 'marakeng o ntseng o eketseha oa lefatše.

Automatic high speed flute laminator, re 'nile ra tšepa ka tieo ho theha kamano e le' ngoe e ntle ea nako e telele ea khoebo le k'hamphani ea hau e hlomphuoang e nahanne ka monyetla ona, e thehiloeng ho lekanang, ho thusa le ho hapa khoebo ea ho hapa ho tloha joale ho fihlela nakong e tlang.