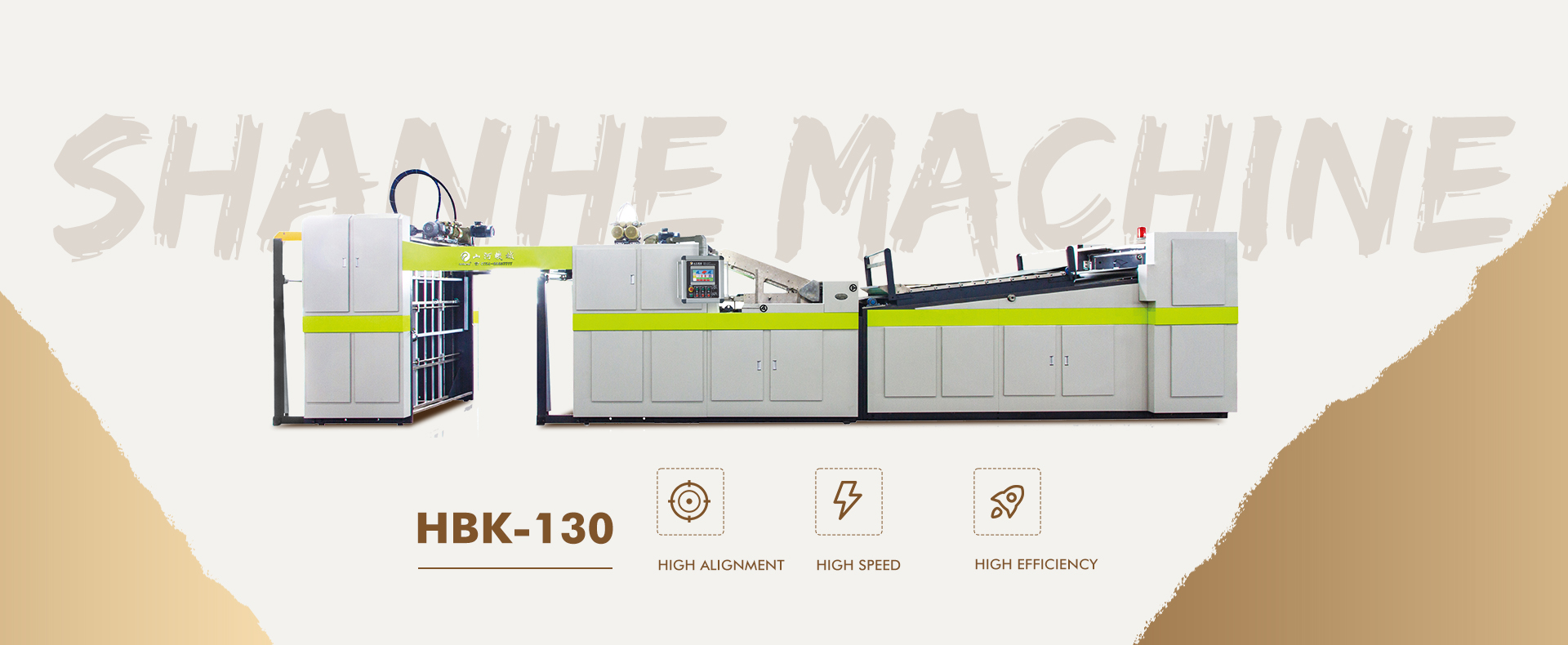

HBK-130 Mochini oa Lamination oa Cardboard o Iketselitsoeng

Tlhaloso e Khutšoanyane:

Model HBK Automatic cardboard lamination machine ke SHANHE MACHINE's high-end smart laminator bakeng sa laminating sheet to sheet e nang le tlhophiso e phahameng, lebelo le phahameng le likarolo tse phahameng tse sebetsang hantle. E fumaneha bakeng sa karete ea laminating, pampiri e koahetsoeng le chipboard, joalo-joalo.

Ho nepahala ha pele le ka morao, ka ho le letšehali le ka ho le letona ho phahame haholo. A qeta sehlahiswa ke ke deform ka mor'a lamination, e leng khotsofatsa lamination bakeng sa habeli lehlakoreng la khatiso pampiri lamination, lamination pakeng tsa pampiri tšesaane le teteaneng, 'me hape, lamination ea 3-ply ho 1-ply sehlahisoa. E loketse lebokose la veine, lebokose la lieta, tag ea hang, lebokose la lintho tsa ho bapala, lebokose la limpho, lebokose la litlolo le liphutheloana tsa lihlahisoa tse thata ka ho fetisisa.

Lintlha tsa Sehlahisoa

Li-tag tsa Sehlahisoa

BONTŠA SEHLAHISO

TS'ELISO

| HBK-130 | |

| Max. Boholo ba Pampiri(mm) | 1280(W) x 1100(L) |

| Min. Boholo ba Pampiri(mm) | 500(W) x 400(L) |

| Botenya ba Leqephe le ka Holimo(g/㎡) | 128-800 |

| Botenya ba Leqephe le Tlase(g/㎡) | 160 - 1100 |

| Max. Lebelo la ho sebetsa(m/min) | 148m/min |

| Max. Sehlahisoa(pcs/hr) | 9000 - 10000 |

| Mamello(mm) | ±0.3 |

| Matla(kw) | 17 |

| Boima ba Mochini(kg) | 8000 |

| Boholo ba Mochini(mm) | 12500(L) x 2050(W) x 2600(H) |

| Lintlha | 380 V, 50 Hz |

LIEKETSENG

A. Full Auto Intelligent Electronic Control System

Mochini o sebelisa sistimi ea taolo ea motsamao ho sebetsa le PLC ho hlokomela taolo ea othomathike. Sebaka sa "remote controller" le "servo motor" se lumella mosebeletsi ho beha boholo ba pampiri skrineng sa ho ama ebe o lokisa leqephe le kaholimo le boemo ba leqephe le tlase la ho romella ka bo eona. Thepa ea seporo se thellang e tsoang kantle e etsa hore boemo bo nepahale; karolong ea ho hatisa ho boetse ho na le remote control bakeng sa ho lokisa boemo ba ka pele le ka morao. Mochini o na le ts'ebetso ea polokelo ea memori ho hopola sehlahisoa se seng le se seng seo o se bolokileng. HBZ e fihla ho automation ea 'nete e nang le ts'ebetso e felletseng, tšebeliso e tlase, ts'ebetso e bonolo le ho ikamahanya le maemo ho matla.

B. Lisebelisoa tsa Motlakase

SHANHE MACHINE boemo ba mochini oa HBK holim'a maemo a indasteri ea Europe. Mochine oohle o sebelisa lihlahisoa tse tummeng tsa machaba, tse kang Trio (UN), P + F (GER), Siemens (GER), Omron (JPN), Yaskawa (JPN), ABB (FRA), Schneider (FRA), joalo-joalo Ba tiisa botsitso le ho tšoarella ha mochine. Taolo e kopaneng ea PLC hammoho le lenaneo la rona le itlhophiselitseng le hlokomela boqhetseke ba mechatronics ho nolofatsa mehato ea ts'ebetso le ho boloka litšenyehelo tsa basebetsi.

C. Mofepi Habedi

Enjene ea servo e ikemetseng e laola li-feeders tsa holimo le tlase ho romella pampiri. Ho bala ka lebelo le phahameng ha ho matha, ho tsamaisa ka boreleli, ho loketse pampiri ea khatiso e fapaneng; re lahla mokhoa oa khale oa phetisetso ea mochini, ho fumana ts'ebetso e phahameng ea lamination ea pampiri e nyane, e leng monyetla oa pele oa SHANHE MACHINE HBK-130.

Sebelisa sehlahisoa se ikemetseng sa R&D sa SHANHE MACHINE: phepelo ea phepelo, e nang le mohopolo o phahameng oa khatiso o sebelisang mochini oa phepelo, ho huloa habeli + ho fetisoa ha moea ho matlafalitsoeng ka mokhoa oa ho fepa, haholo-holo e ka monya 1100g/㎡ lakane e tlase ka ho monya hantle; li-feeders tsa holimo le tlase kaofela li na le sethala sa ho kenya pele sa mofuta oa gantry, se siea sebaka le nako ea ho kenya pampiri pele, e bolokehile ebile e ka tšeptjoa. E khotsofatsa litlhoko tsa lebelo le phahameng ka ho felletseng.

Sistimi e ncha e ikhethileng ea ts'ireletso:

1. ha feeder e khutlela ho zero, lebelo le tla theoha ka tsela e iketsang ho fokotsa ts'usumetso ho sefepi.

2. Haeba feeder e sa hlophisoa bocha, mochini o ke ke oa qala e le ho thibela litšila tsa pampiri tse bakiloeng ke ho se sebetse hantle.

3. Haeba lisebelisoa tsa mochini li sa romelloa letlapa le ka holimo, mochini o fepelang pampiri o tla emisa; haeba lakane e ka tlaase e se e ntse e romela, karolo ea lamination e tla emisa ka mokhoa o itekanetseng ho netefatsa hore ha ho na lakane e khomaretsoeng e ke keng ea romeloa ho karolo ea khatiso.

4. Mochini o tla emisa ka bohona haeba lakane e ka holimo le e ka tlase e khomaretsoe.

5. Re kenya litlhophiso tsa data tsa mats'eliso a karolo e ka tlase ea phepelo ea pampiri ho etsa hore tokiso e nepahale haholoanyane.

D. Lamination le Boemo Karolo

Sebelisa servo motor ha u khanna ho lekana pampiri ea boholo bo fapaneng. Motion molaoli ea lekanya ho nepahala ha lolahano ka lebelo le phahameng, ka pele gauge maemo holimo le tlase lakane ka nako e tšoanang, hlokomela phahameng ho nepahala lamination ka lebelo le phahameng.

Moralo oa mohopolo o mocha o arolang sekala sa pele le phetisetso ea mantlha, ka thoko eketsa enjene ea servo ho laola, ho beha maemo le ho latedisa. Ka lenaneo le iketselitseng la SHANHE MACHINE, kannete le hlokomela ho nepahala ho phahameng ka lebelo le phahameng, ho ntlafatsa haholo lebelo la tlhahiso, katleho le taolo.

E. Mokhoa oa ho khanna

Mochini o sebelisa mabili a khokahanyo a tsoang kantle ho naha le mabanta phetisong. Tlhokomelo mahala, lerata le tlase, ho nepahala ho phahameng. Re khutsufatsa liketane tsa ho lokisoa holimo le tlase, re eketsa li-servo motor tse sebetsang, re khutsufatsa potoloho ea ts'ebetso, re fokotsa phoso ea ketane le ho eketsa lebelo, ho hlokomela lakane e phethahetseng ho lamination.

F. Glue Coating System

Ts'ebetsong ea lebelo le phahameng, e le ho koahela sekhomaretsi ka ho lekana, Shanhe Machine e rala karolo ea ho roala e nang le rolara e khethehileng ea ho roala le sesebelisoa se thibelang sekhomaretsi ho rarolla bothata ba ho fafatsa sekhomaretsi. Sesebelisoa sa sekhomaretsi se felletseng se tlatselletsang le se sebelisoang hape se thusa ho qoba tšenyo ea sekhomaretsi. Ho latela litlhoko tsa sehlahisoa, basebelisi ba ka fetola botenya ba sekhomaretsi ka lebili le laolang; ka rolara e khethehileng ea rabara e nang le metsero e rarolla ka katleho bothata ba ho phatloha ha sekhomaretsi.

lihlahisoa tse amanang

-

HBF-145/170/220 Full-auto High Speed All-in-One...

-

HBZ-145/170/220 Full-auto High Speed Flute Lami...

-

HMC-1050 Automatic Die Cutting Machine

-

Mochini oa ho itšeha oa HMC-1080 o Iketsetsang oa ho Seha

-

HMC-1080DE Automatic Deep Embossing Die Cutter ...

-

HMC-1080HD Automatic Die Cutting Machine (600T ...

-

Mochini oa Varnishing oa HSG-120 o Felletseng o Phahameng ka ho Fetisisa

-

Mochini oa Varnish ea HSG-120D o Felletseng o Phahameng ka ho Fetisisa

-

Mochini oa Varnish ea HSG-120UV o Felletseng ka lebelo le phahameng

-

HSY-120 Full-auto High Speed Varnishing & ...

-

HYG-120 Full-auto High Speed Calndering Machine

-

HTJ-1050 Automatic Hot Stamping Machine

-

HTJ-1060 Automatic Hot Stamping Machine

-

HTJ-1080 Automatic Hot Stamping Machine

-

QLF-110/120 Automatic High Speed Film Laminatin...

-

QYF-110/120 Full-auto pre-coating Film Laminator