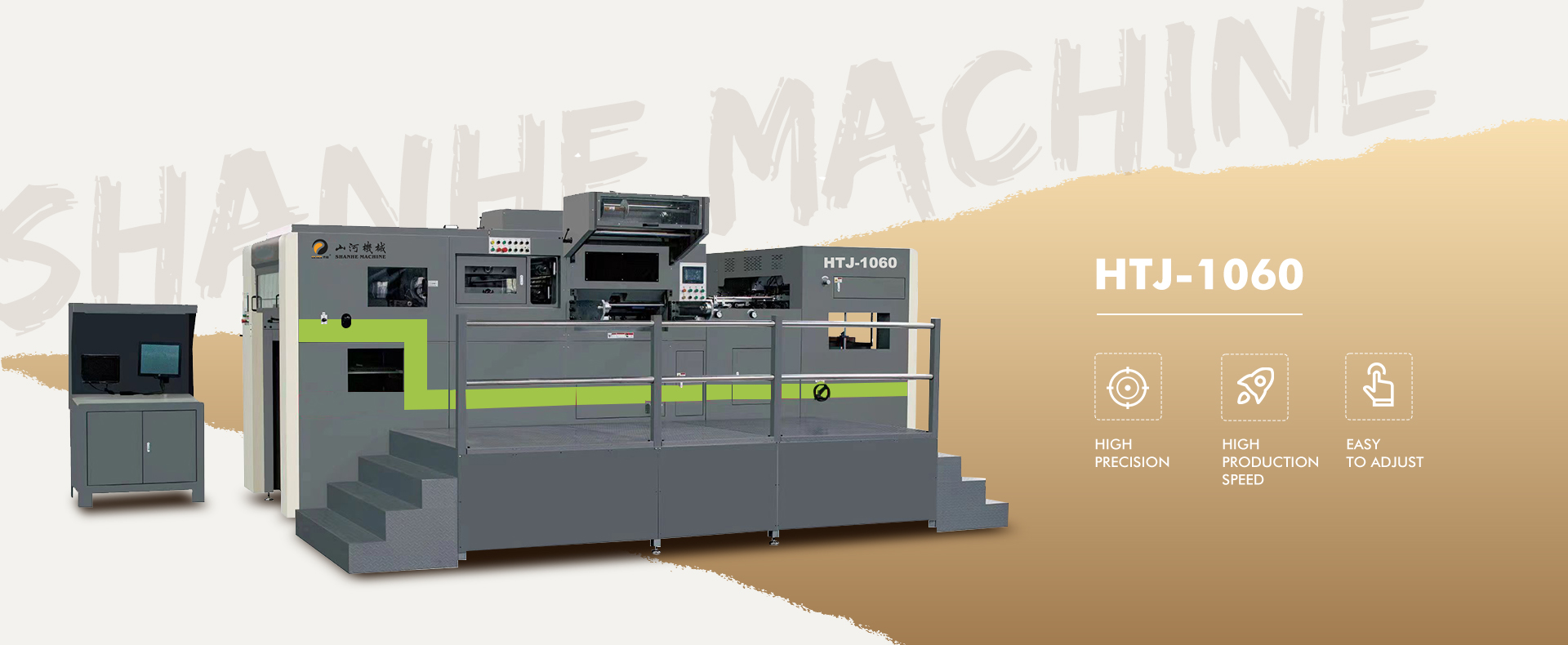

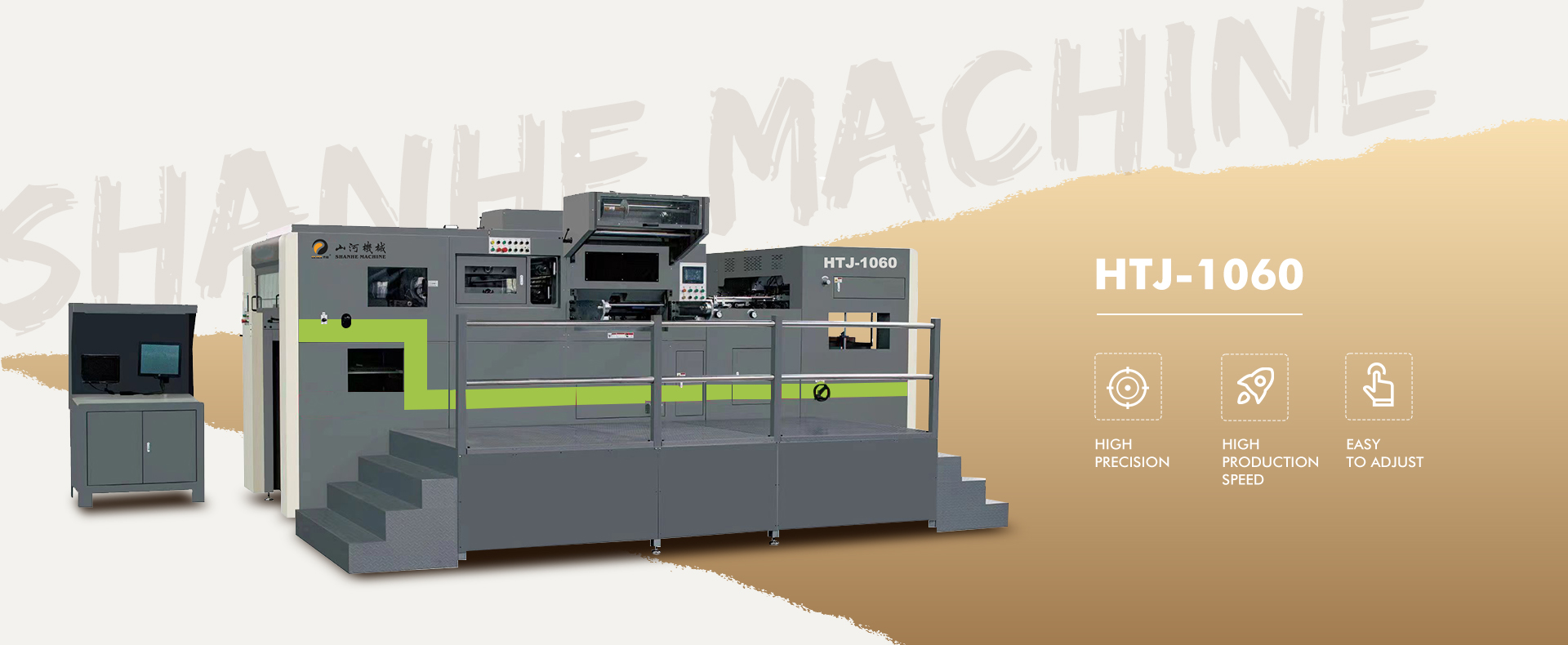

Lub feeder muaj lub luag haujlwm hnyav, tsim tshwj xeeb uas muaj lub zog nqus thiab tuaj yeem xa tawm cov duab los qhia, corrugated, thiab grey board ntawv. Txhawm rau kom muaj kev ruaj ntseg ntawm daim ntawv suction, lub taub hau suction tuaj yeem hloov pauv lub nqus lub kaum sab xis hauv cov lus teb rau qhov ua li cas daim ntawv deforming. Muaj nuj nqi rau kev siv kom raug thiab kev hloov kho yooj yim muaj. Precise thiab txhim khu kev qha ntawv pub rau ob daim ntawv tuab thiab nyias.