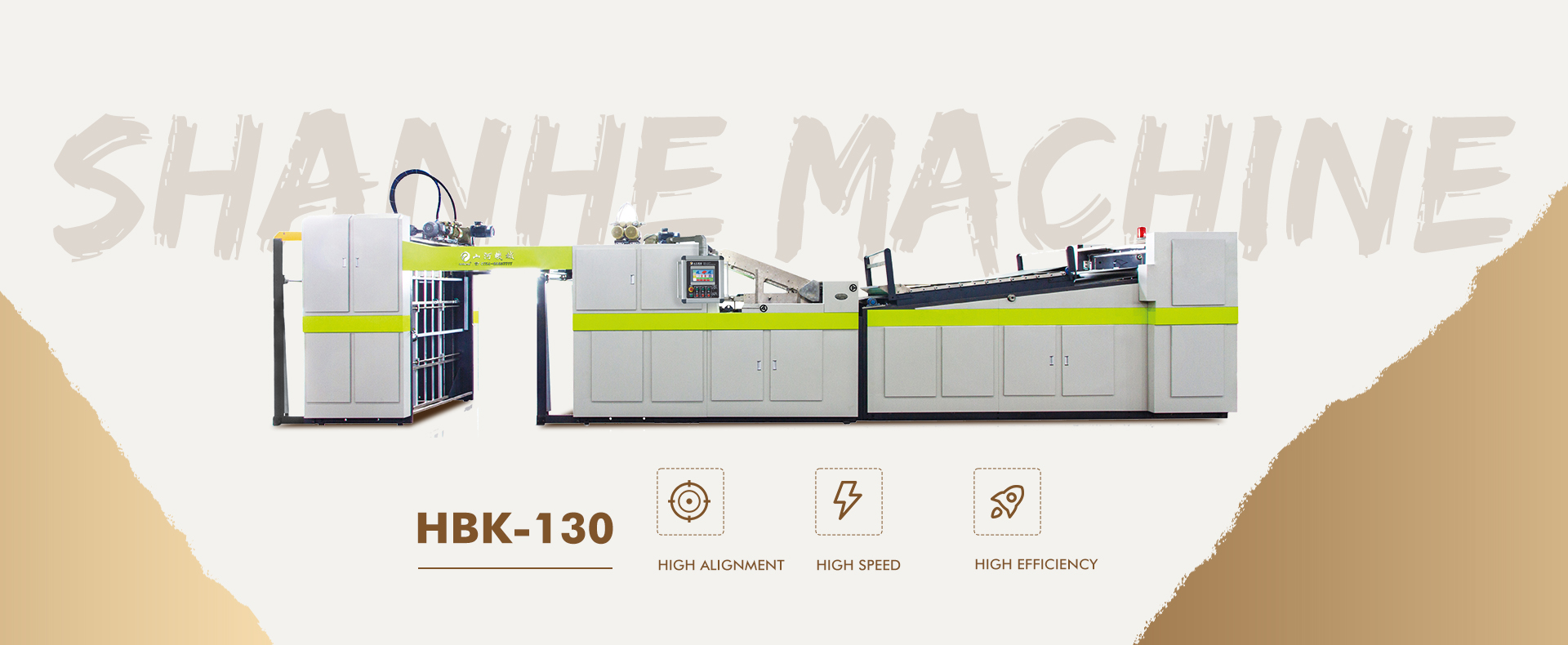

Siv SHANHE MACHINE tus ywj pheej R & D patented khoom: feeder conveying, nrog high-end tshuab luam ntawv siv feeder lub tswv yim tsim, ob chav suction + plaub conveying cua suction ntxiv dag zog rau kev pub mis, maximally nqus tau 1100g / ㎡ hauv qab ntawv nrog precision suction; nce thiab nqis feeders tag nrho muaj gantry-hom pre-loading platform, tawm qhov chaw thiab sij hawm rau pre-loading ntawv, muaj kev nyab xeeb thiab txhim khu kev qha. Nws tag nrho txaus siab rau kev kub ceev khiav txoj cai.

Tshiab tshwj xeeb tsis siv neeg tiv thaiv system:

1. Thaum feeder rov qab mus rau xoom, kev ceev yuav qeeb qeeb kom txo tau qhov cuam tshuam rau lub feeder.

2. Yog tias lub feeder tsis rov pib dua, lub tshuab yuav tsis pib kom tiv thaiv cov ntawv pov tseg uas tshwm sim los ntawm kev ua haujlwm tsis zoo.

3. Yog hais tias lub tshuab tsis tau xa cov ntawv saum toj kawg nkaus, cov ntawv hauv qab yuav tsum nres; yog tias daim ntawv hauv qab twb xa lawm, qhov lamination yuav tsum nres kom ntseeg tau tias tsis muaj daim ntawv nplaum yuav tsis raug xa mus rau qhov nias.

4. Lub tshuab yuav nres tau yog tias daim ntawv saum toj thiab hauv qab daig.

5. Peb ntxiv cov ntawv hauv qab feeder theem them cov ntaub ntawv teeb tsa kom ua kom qhov kev sib raug zoo ntau dua.