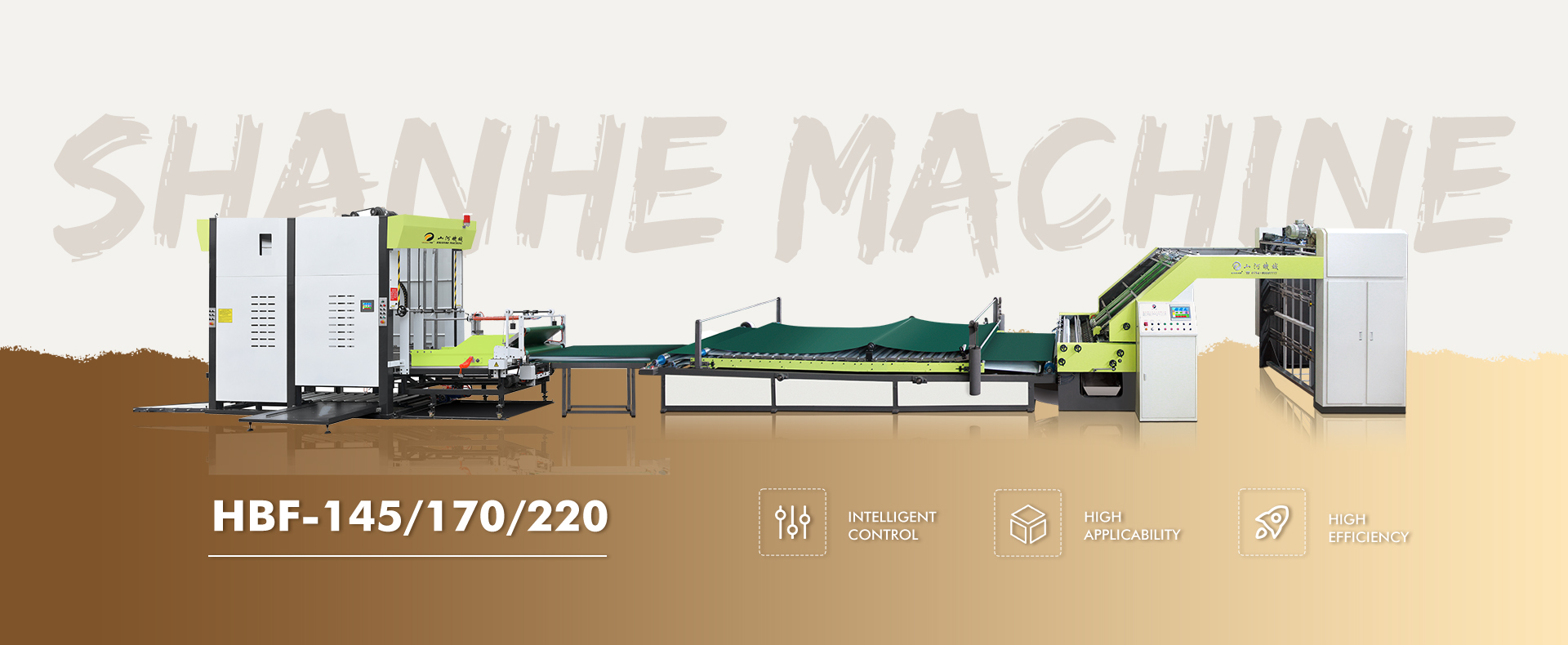

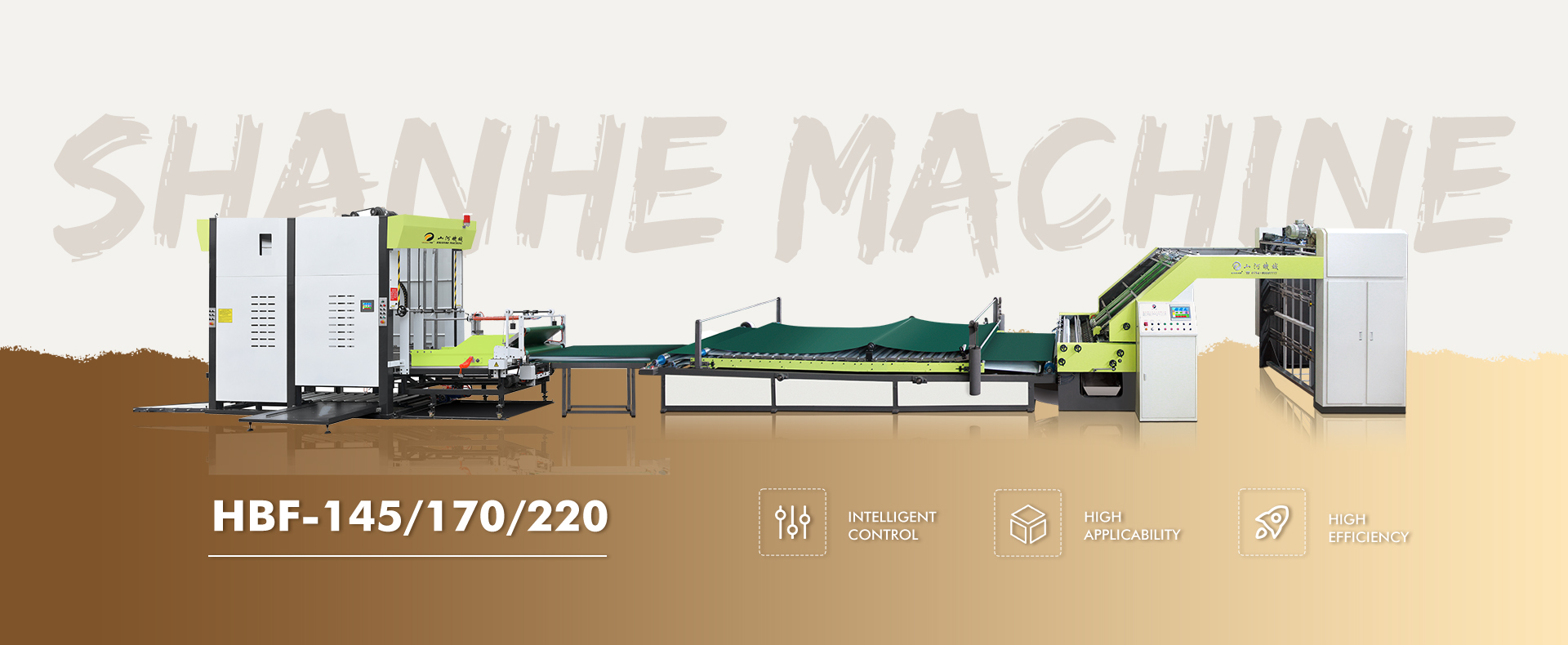

Motar Servo tana fitar da bel ɗin tsotsa don aika takarda ta ƙasa wanda ya haɗa da kwali, allon launin toka da 3-ply, 4-ply, 5-ply da 7-ply corrugated board tare da A/B/C/D/E/F/N- sarewa. . Aiko yana da santsi kuma daidai.

Tare da ƙirar tsotsa mai ƙarfi, injin zai iya aika takarda tare da kauri tsakanin 250-1100g/㎡.

HBZ-170 kasa takardar ciyar part yana amfani da dual-vortex famfo tare da dual-solenoid bawul iko, da nufin a 1100 + mm nisa takarda, na iya fara na biyu iska famfo ƙara iska tsotsa girma, aiki mafi alhẽri a kan isar warping da lokacin farin ciki corrugation jirgin.