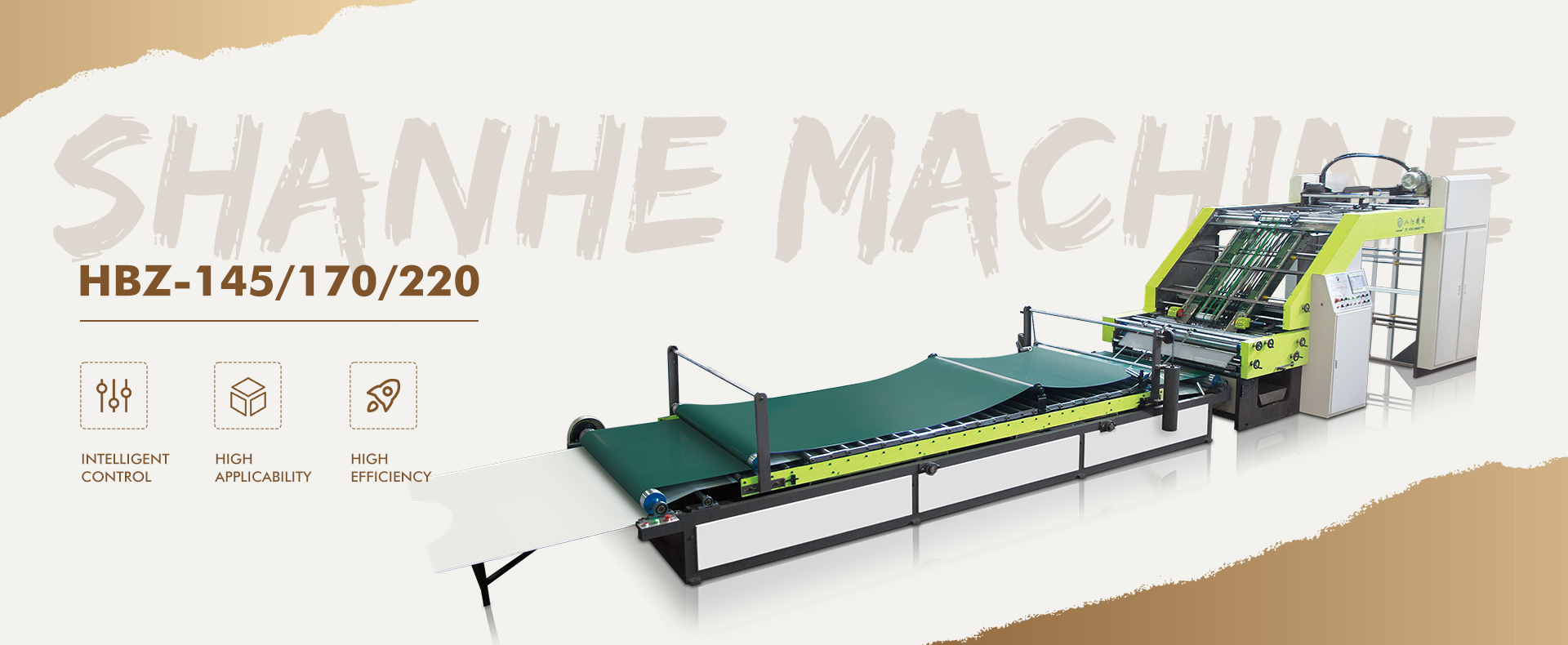

Full-auto High Speed Flute Laminating Machine

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for Full-auto High Speed Flute Laminating Machine, As we are moving forward, we keep an eye on our ever-expanding product range and make improvement to our services.

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for Flute Laminator, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

PRODUCT SHOW

SPECIFICATION

|

HBZ-145 |

|

| Max. Sheet Size(mm) | 1450(W) x 1300(L) / 1450(W) x 1450(L) |

| Min. Sheet Size(mm) | 360 x 380 |

| Top Sheet Thickness(g/㎡) | 128 - 450 |

| Bottom Sheet Thickness(mm) | 0.5 – 10mm (when laminate cardboard to cardboard, we require bottom sheet to be above 250gsm) |

| Suitable Bottom Sheet | Corrugated board (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply and 7-ply), grey board, cardboard, KT board, or paper to paper lamination |

| Max. Working Speed(m/min) | 160m/min (when flute length is 500mm, machine can reach max. speed 16000pcs/hr) |

| Lamination Accuracy(mm) | ±0.5 – ±1.0 |

| Power(kw) | 16.6 |

| Weight(kg) | 7500 |

| Machine Dimension(mm) | 13600(L) x 2200(W) x 2600(H) |

|

HBZ-170 |

|

| Max. Sheet Size(mm) | 1700(W) x 1650(L) / 1700(W) x 1450(L) |

| Min. Sheet Size(mm) | 360 x 380 |

| Top Sheet Thickness(g/㎡) | 128 - 450 |

| Bottom Sheet Thickness(mm) | 0.5-10mm (for cardboard to cardboard lamination: 250+gsm) |

| Suitable Bottom Sheet | Corrugated board (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply and 7-ply), grey board, cardboard, KT board, or paper to paper lamination |

| Max. Working Speed(m/min) | 160m/min (when running 400x380mm size paper, machine can reach max. speed 16000pcs/hr) |

| Lamination Accuracy(mm) | ±0.5 – ±1.0 |

| Power(kw) | 23.57 |

| Weight(kg) | 8500 |

| Machine Dimension(mm) | 13600(L) x 2300(W) x 2600(H) |

|

HBZ-220 |

|

| Max. Sheet Size(mm) | 2200(W) x 1650(L) |

| Min. Sheet Size(mm) | 600 x 600 / 800 x 600 |

| Top Sheet Thickness(g/㎡) | 200-450 |

| Suitable Bottom Sheet | Corrugated board (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply and 7-ply), grey board, cardboard, KT board, or paper to paper lamination |

| Max. Working Speed(m/min) | 130m/min |

| Lamination Accuracy(mm) | < ± 1.5mm |

| Power(kw) | 27 |

| Weight(kg) | 10800 |

| Machine Dimension(mm) | 14230(L) x 2777(W) x 2500(H) |

ADVANTAGES

Motion control system for coordinating and main controlling.

Minimal sheets distance can be 120mm.

Servo motors for alignment of top sheets’ front and back laminating position.

Automatic sheets tracking system, top sheets trace bottom sheets.

Touch screen for controlling & monitoring.

Gantry type pre-loading device for easy placing top sheet.

FEATURES

A. INTELLIGENT CONTROL

● American Parker Motion Controller complement the tolerance to control the alignment

● Japanese YASKAWA Servo Motors allow machine to perform more stable and fast

C. CONTROLLING SECTION

● Touch Screen Monitor, HMI, with CN/EN version

● Set sheets size, change sheets distance and monitoring the operation state

E. TRANSMISSION SECTION

● Imported timing belts solve problem of inaccurate lamination due to the worn-out chain

Corrugated Board B/E/F/G/C9-flute 2-ply to 5-ply

Duplex Board

Grey Board

H. PRE-LOADING SECTION

● Easier for placing top sheet pile

● Japanese YASKAWA Servo Motor

DETAILS

SHANHE MACHINE provides a whole set of training lessons for printing and packaging companies, which

includes lamination lesson, glue mixing lesson, how to have good lamination result with high toughness,

high precision and reasonable water content, how to adjust pressing part pressure and how to adjust flip

flop stacker. We will share all our experience and practice managing which we accumulated in the past 30

years.