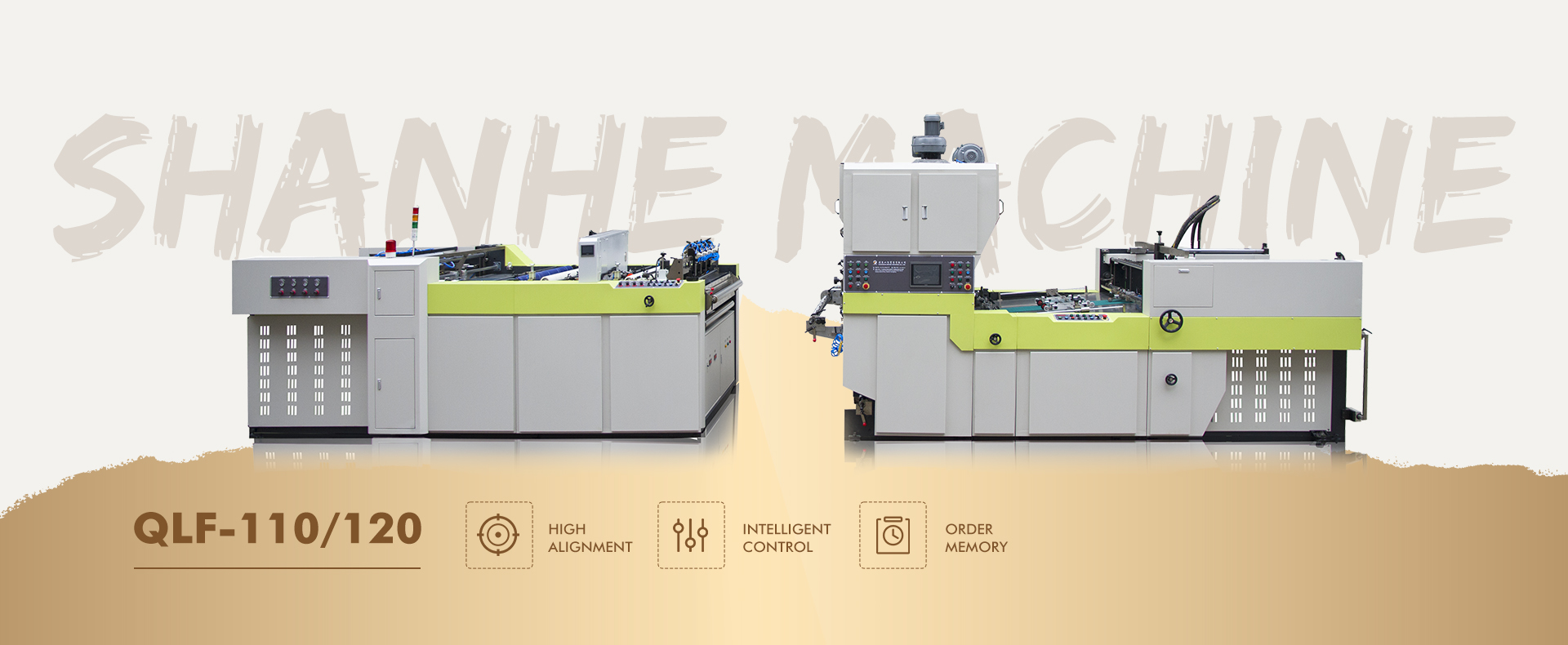

Automatic High Speed Film Laminating Machine

We’re going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Automatic High Speed Film Laminating Machine, With a wide range, top quality, realistic costs and good company, we are going to be your most effective company partner. We welcome new and aged clients from all walks of daily life to call us for long term small business interactions and acquiring mutual achievements!

We’re going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for China Film Laminating Machine, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers’ faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end products, to do specialist solutions.

PRODUCT SHOW

SPECIFICATION

|

QLF-110 |

|

| Max. Paper Size(mm) | 1100(W) x 960(L) / 1100(W) x 1450(L) |

| Min. Paper Size(mm) | 380(W) x 260(L) |

| Paper Thickness(g/㎡) | 128-450 (paper below 105g/㎡ needs manual cutting) |

| Glue | Water-based glue / Oil-based glue / No glue |

| Speed(m/min) | 10-80 (the max. speed can reach 100m/min) |

| Overlap Setting(mm) | 5-60 |

| Film | BOPP / PET / metalized film /thermal film (12-18 micron film, glossy or matt film) |

| Working Power(kw) | 40 |

| Machine Size(mm) | 10385(L) x 2200(W) x 2900(H) |

| Machine Weight(kg) | 9000 |

| Power Rating | 380 V, 50 Hz, 3-phase, 4-wire |

|

QLF-120 |

|

| Max. Paper Size(mm) | 1200(W) x 1450(L) |

| Min. Paper Size(mm) | 380(W) x 260(L) |

| Paper Thickness(g/㎡) | 128-450 (paper below 105g/㎡ needs manual cutting) |

| Glue | Water-based glue / Oil-based glue / No glue |

| Speed(m/min) | 10-80 (the max. speed can reach 100m/min) |

| Overlap Setting(mm) | 5-60 |

| Film | BOPP / PET / metalized film /thermal film (12-18 micron film, glossy or matt film) |

| Working Power(kw) | 40 |

| Machine Size(mm) | 11330(L) x 2300(W) x 2900(H) |

| Machine Weight(kg) | 10000 |

| Power Rating | 380 V, 50 Hz, 3-phase, 4-wire |

ADVANTAGES

Servo shaft-less high speed feeder, suitable for all printing sheets, can run stably at high speed.

Large diameter roller design (800mm), use imported seamless tube surface with hard chrome plating, increase the film brightness, and thus improve product quality.

Electromagnetic heating mode: the heat utilization rate can reach 95%, so machine heats up twice faster than before, save electricity and energy.

Thermal energy circulation drying system, the whole machine uses 40kw/hr electricity consumption, save more energy.

Increase efficiency: intelligent control, production speed up to 100m/min.

Cost reduction: high precision coated steel roller design, precise control of glue coating amount, save glue and increase speed.

DETAILS

Auto Edge-landing System

Use servo motor along with control system to replace the traditional step-less speed change device, so that the precision of overlap position is very accurate, so as to meet the high requirements of “no overlap precision” of printing enterprises.

The glue section has an automatic inspection system. When the broken film and broken paper occurs, it will automatically alarm, slow down and stop, so as to prevent the paper and film from being rolled into the roller, and solve the problem of difficult to clean and roll is broken.

Automatic High Speed Film Laminating Machine is consist of auto shaft-less servo controlled feeder, auto slitting unit, auto paper stacker, energy-saving oil insulated-roller, magnetic powder tension controller (optional manual/automatic), hot air dryer with auto thermostatic control and other advantages. It’s an integration of intelligent, efficient, safe, energy saving and simple, is recognized by the majority of users.